Description

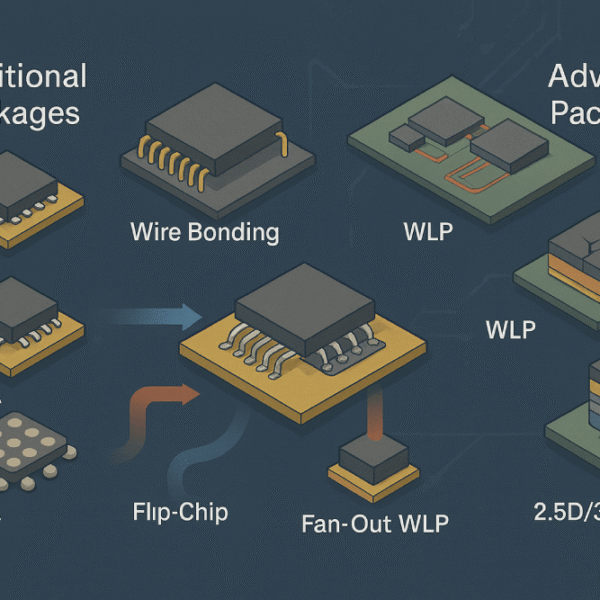

This intensive 5-hour course provides a comprehensive overview of advanced failure analysis and inspection techniques used in semiconductor packaging. Participants will learn how to apply key electrical, non-destructive, visual, and microscopic test methods—as well as automated inspection systems—to ensure package integrity, enhance yield, and troubleshoot defects effectively.

➢ Duration of Modules

| Module | Duration |

| 1 Electrical Testing | 1.5 Hours |

| 2 Non-Destructive Inspection | 1.5 Hours |

| 3 Visual Inspection Systems and Automated Failure Analysis | 0.75 Hour |

| 4 Failure Analysis Techniques | 1.25 Hours |

| Total | 5 Hours |

➢ Learning Outcomes

Upon completion of this course, participants will be able to:

- Implement parametric and functional electrical tests to verify package performance.

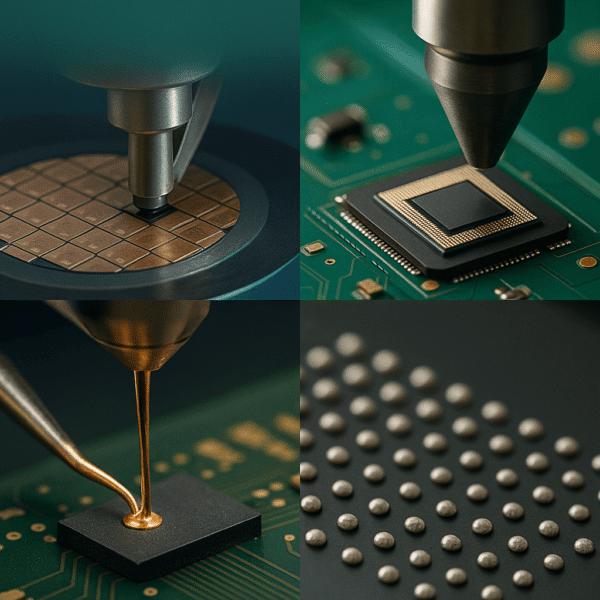

- Utilize non-destructive X-ray, acoustic, and optical inspection methods for defect detection.

- Set up and operate visual inspection systems, leveraging AI-based anomaly detection.

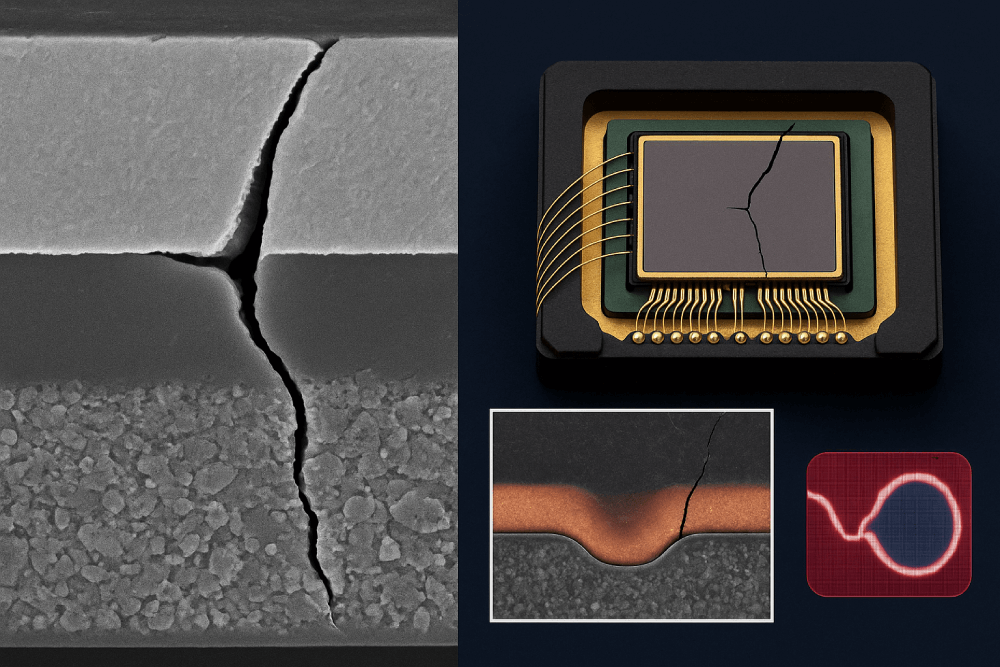

- Execute advanced failure-analysis workflows, including cross-sectional SEM, FIB-SEM, TEM, and decapsulation techniques.

- Analyze data using SPC and yield-mapping strategies to drive process improvements.

- Integrate inspection findings with manufacturing execution systems for real-time quality control.

➢ Target Audience

This course is designed for:

- Packaging engineers and process development engineers in semiconductor fabrication.

- Failure analysis specialists seeking advanced inspection and diagnostic skills.

- Quality and reliability engineers responsible for package integrity.

- R&D professionals and lab technicians working on semiconductor assembly and test.

- Managers overseeing yield enhancement, quality assurance, and failure-analysis teams.

Reviews

There are no reviews yet.