Description

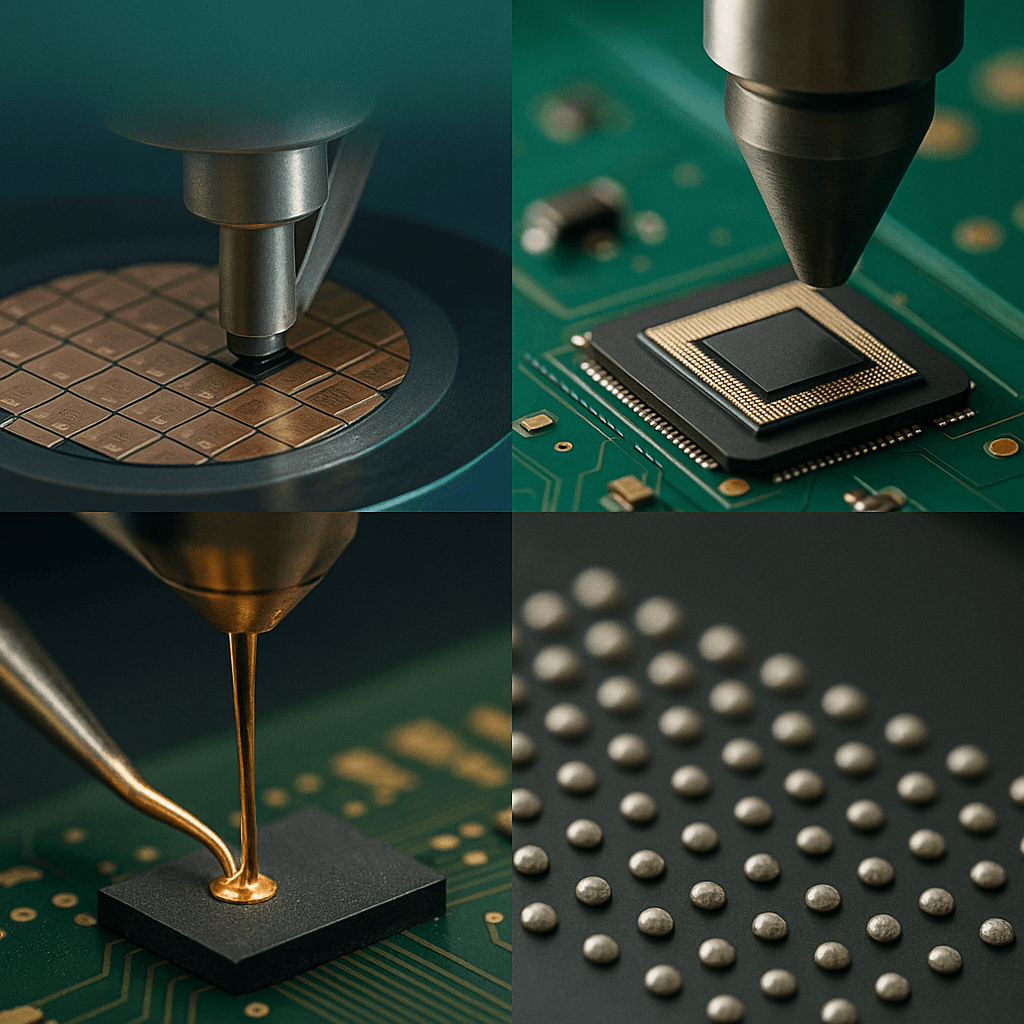

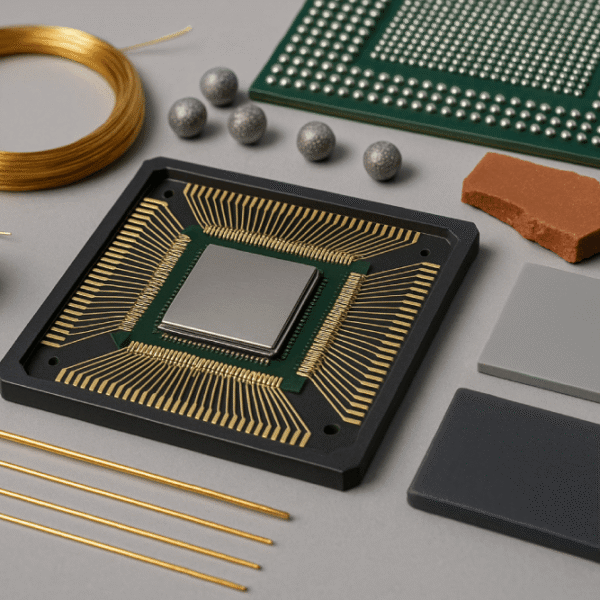

This intensive 9-hour module delves into the critical manufacturing steps that transform a bare die into a fully encapsulated, ready-to-use semiconductor package. Participants will explore best-practice techniques—from wafer thinning and die singulation through advanced interconnect formation and final encapsulation—gaining hands-on insight into equipment, materials, and process controls essential for modern IC packaging operations.

➢ Curriculum Duration

Total Contact Hours: 9 hours

- A. Die Preparation (1.5 hrs)

– Wafer thinning

– Dicing and singulation - B. Die Attachment (1 hr)

– Die-attach adhesives

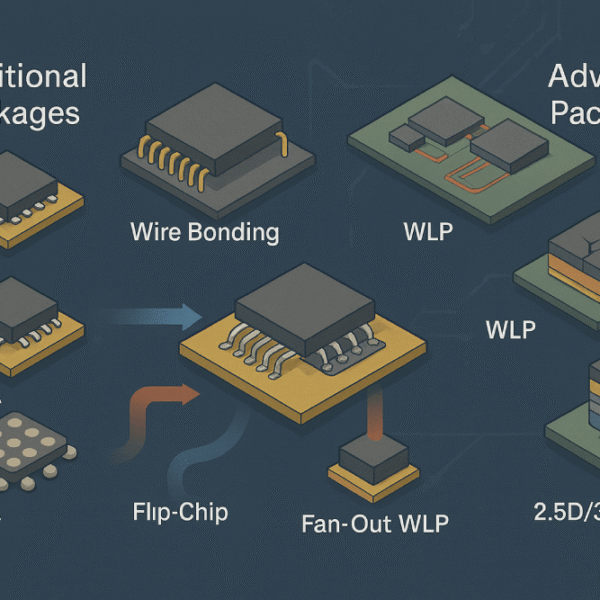

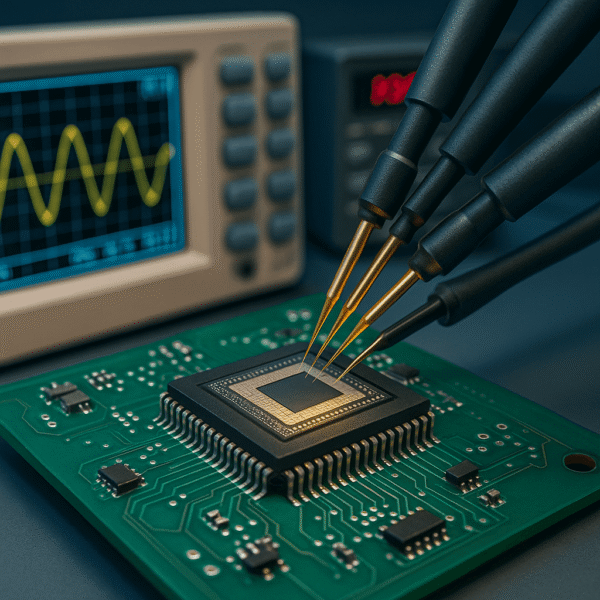

– Eutectic die-attach methods - C. Interconnect Formation (2.5 hrs)

– Wire bonding (gold, aluminum)

– Flip-chip processes (solder bumping, under-bump metallurgy) - D. Cleaning and Underfill (1 hr)

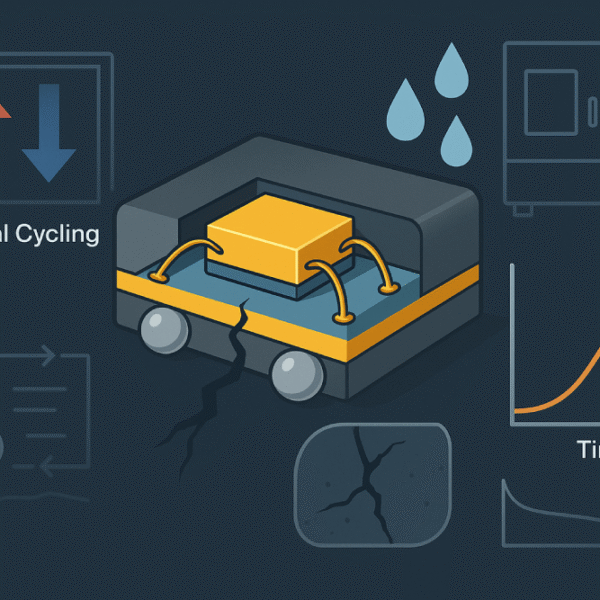

– Flux cleaning techniques

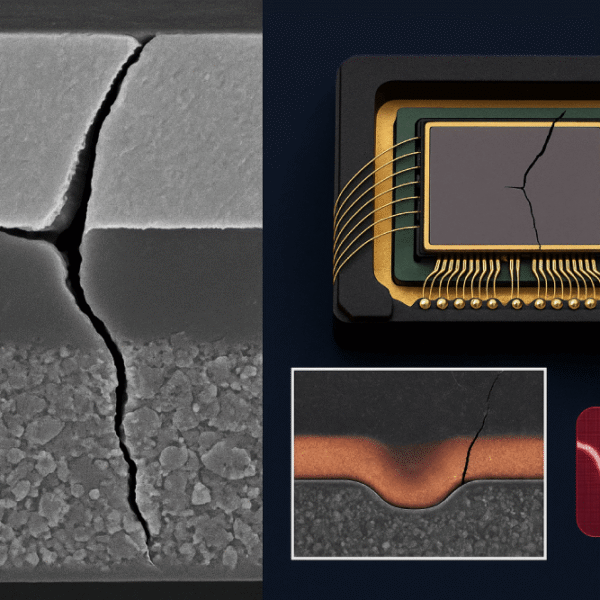

– Underfill materials and process - E. Encapsulation and Marking (1.5 hrs)

– Molding compounds and encapsulation methods

– Laser marking - F. Ball Attach and Reflow (1 hr)

– Solder ball attachment

– Reflow profiling - G. Equipment and Operations (1.5 hrs)

– IC packaging toolsets

– Cleanroom protocols and safety

➢ Skills You’ll Gain

- Mastery of wafer thinning and precision dicing techniques

- Selection and application of die-attach adhesives and eutectic systems

- Proficiency in wire bonding and flip-chip interconnect formation

- Understanding of flux cleaning and underfill process optimization

- Knowledge of encapsulation materials, molding methods, and laser marking

- Expertise in solder ball attachment and thermal profiling for reflow

- Operational competency with IC packaging equipment and cleanroom best practices

➢ Target Audience

This module is designed for:

- Process engineers and technicians in semiconductor packaging

- Manufacturing engineers seeking to optimize yield and reliability

- Quality engineers focused on package integrity and failure analysis

- R&D professionals developing advanced packaging solutions

- Cleanroom operations personnel and equipment maintenance staff

Participants will leave with both theoretical understanding and practical insights to implement robust, high-throughput packaging processes in production environments

Reviews

There are no reviews yet.