Description

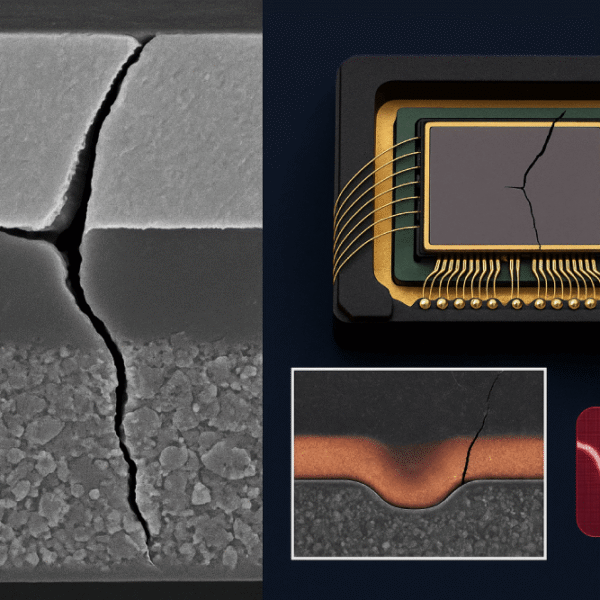

This intensive module delves into advanced reliability and qualification techniques for semiconductor packages. Participants will explore standardized stress tests, environmental qualification protocols, and statistical methods for lifetime prediction. Emphasis is placed on JEDEC standards, failure-mode analysis, and data-driven reporting to prepare attendees for real-world packaging challenges.

➢ Main Takeaway

Equip engineers and technologists with hands-on methodologies for stress testing, environmental qualification, and lifetime prediction of semiconductor packages to ensure robust, high-reliability products.

➢ Duration of Modules

| Module | Duration |

| 1 Thermal Cycling and Thermal Shock | 1.25 Hours |

| 2 Highly Accelerated Stress Test (HAST) and High-Temperature Storage (HTSL) | 1.25 Hours |

| 3 Moisture Sensitivity Level (MSL) and JEDEC Standards | 1.25 Hours |

| 4 Data Analysis for Lifetime Prediction | 1.25 Hours |

| Total | 5 Hours |

➢ Learning Outcomes

By the end of this course, participants will be able to:

- Apply JEDEC thermal cycle and shock profiles to simulate real-world thermal fatigue.

- Operate HAST and HTSL chambers, set bias conditions, and interpret environmental stress data.

- Classify moisture sensitivity levels (MSL), implement preconditioning protocols, and manage traceability.

- Use Weibull, Arrhenius, Coffin-Manson, and Black’s models for accelerated life-data analysis.

- Develop comprehensive reliability reports including MTBF, FIT rates, and failure thresholds.

➢ Target Audience

This course is ideal for:

- Semiconductor packaging engineers seeking advanced qualification skills.

- Reliability and test engineers responsible for stress testing and failure analysis.

- Quality assurance professionals overseeing package qualification standards.

- R&D scientists developing next-generation package technologies.

- Project managers coordinating reliability programs in semiconductor manufacturing.

Reviews

There are no reviews yet.